The role of silica nanoparticles on modifying oilwell cement properties- A Review

Info: 8299 words (33 pages) Dissertation

Published: 9th Dec 2019

Tagged: Chemistry

Abstract: Due to high potential of improving a wide range of fundamental properties in oilwell cement, nanotechnology has gained widespread attention to be used in petroleum industry in recent years. Many studies done so far show that inclusion of nanosilica into oilwell cement enhances cement properties such as strength and durability. The enhancement of cement properties is attributed by ultra-fine particle size and high specific surface area of nanosilica. It was observed from the previous researches that addition of silica nanoparticles enhances the properties of both fresh and hardened cement. Nanosilica can react with excess CH, generate additional C-H-S and refine the pores resulting into denser and compact microstructure cement for effective annular seal. The present study reviews the roleof silica nanoparticles to enhance cement properties for improved oilwell integrity.

Keywords: Oilwell cement; Nanosilica; Nanoparticles; Mechanical properties; Microstructure.

1. Introduction

Primary well cementing is one of the most important process during drilling and completion of oilwells. It is the process of injecting cement slurry into the annular space between casing and formations exposed to the drilled wellbore. The cement slurry is then given a period of time to harden, to make a strong and impermeable annular seal. The main objective of primary cementing in oil and gas wells is to provide zonal isolation, provide structural support for the casing, and protect the casing from attack by corrosive fluids [1]. Besides, cement is deployed into the wells for squeeze jobs (remedial cementing) and during the well abandonment phase (plug cementing). These cement plugs and annular cement sheaths need to acts as barriers against leakage over the entire life cycle of the well [2].

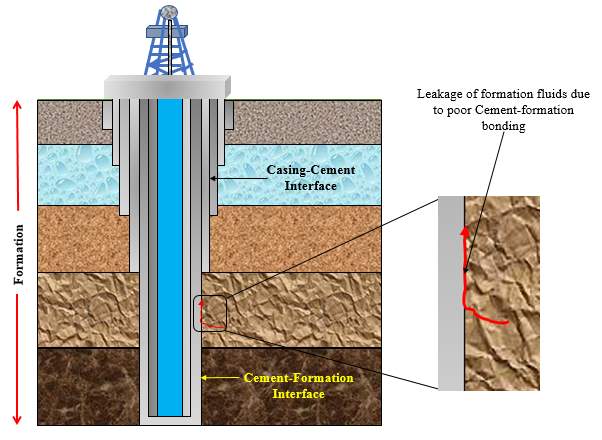

Failure of the cement to perform its basic functions can result into one or more of the following problems; contamination of fresh water aquifers, loss of hydrocarbon reserves in producing wells, loss of injected fluids in injector wells, sustained casing pressure or even a blowout [3]. Over the years, fluid leakage has been reported as a major challenging problem in oil and gas wells. This leakage is associated with fluid flow through the cemented annulus portion of the wellbore. High cost of remediation, production and abandonment as well as environment damage are some of the impacts of fluid leakage into the wellbore. Several studies have shown that chronic leakages are caused by poor interaction of the cement-formation interface or damaged cement sheath (Fig. 1). Nelson and Guillot [4], found that a well may never reach its full production potential without effective cementing. Furthermore, they suggested that oilwell cement must be modified to enhance its functionality. In that regard, recently nanoparticles especially nanosilica have been widely incorporated into cement slurry to improve its performance for ensuring well integrity and long term zonal isolation [5].

Fig.1. Schematic diagram for fluid leakage along the cement-formation interface in the wellbore due to cement failure.

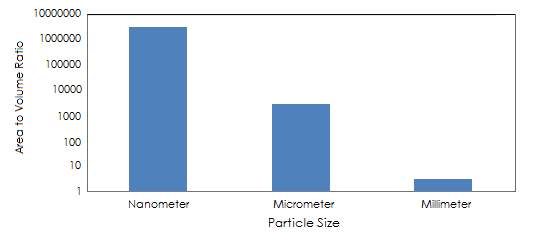

Addition of nanoparticles into cement has gained more importance in oilfields due to the fact that nano-sized particles can modify properties in both fresh and hardened states of cement. Due to their size that ranges from 1-100nm, nanoparticles possess unique properties that differ basically with their macro sized counterparts. Apart from their size effect, nanoparticles have special characteristics including large surface area per volume ratios and higher chemical reactivity which triggers their ability to modify properties in cement. A comparison of the surface area to volume ratio of spherical particles of the same substance with radius of 1mm, 1μm and 1nm was reported by Ref. [2,6]. As indicated in Fig. 2, more than a million fold increase in surface area per volume ratio will be achieved when a particle is converted from a millimeter dimension to a nano-scale. It was summarized that the size effect of nanomaterials compared to macro and micro materials of the same parent substances provide special properties to the nanos that are non -existent in the parent substances [6].

Fig.2. Surface areato volume ratio of the same volume of material, adapted from Ref. [2,6].

The inclusion of silica nanoparticles into cement can result into different effects. Several literatures have reported the accelerating effect in cement paste[7-14]. The mechanism of this working principle is attributed by ultra-fine particle size and high specific surface area of nanosilica because it works as nucleation site for the precipitation of C-S-H gel [9,12,14,15]. These properties of nanosilica can play an important role in the development of high efficient cement for improved well productivity. Due to that nanosilica addition in cement has shown great potential to improve a wide range of fundamental properties of cement such as mechanical strength, setting time, cement hydration, microstructures and durability [15]. The most commonly researched effect of nanosilica in cement is on mechanical strength. Nanosilica particles are capable of adding new functionalities into cement and enhance the compressive strength and durability of the existing cementitious material [6,10]. In this regard, it was reported that that the ratio of tensile to compressive strength of cement without any mechanical properties enhancement is about 0.1[9]. But, when nanomaterials such as nanosilica are incorporated into cement, this ratio increases as high as possible signifying that durability of the cement sheath can be promoted with nanoparticles [9]. Based on that, nanosilica are used in the preparation of cement system used in different wellbore conditions such in high temperature and pressure wells to ensure successful zonal isolation. It is also been reported that cement with nanosilica reduces the possibility of casing collapse and prevents gas migration which is one of the cementing challenges in natural gas wells [16]. The effect of nanosilica in cement composites was also reported by Ref.[17-22].

Some literature reports that silica nanoparticles are used either to replace as part of cement or as an additive in the cement slurry [11]. In both cases, it has been proved that these nanomaterials enhance properties and performance of cement. The presence of nanosilica into oilwell cement paste accelerates the hydration reaction which also slows down the time for wait on cement (WOC). This helps to save rig working hours and finally decreases operational costs [3,10]. On the other hand, though many researchers have reported positive changes in mechanical and chemical properties of nanoparticles added cement, the real mechanism triggering the improvement of properties is not clear[23]. Currently, understanding of the hydration of cement particles and the use of nano-scale materials are most active research areas in cement [16]. A number of publications have already done to describe the role of nanoparticles on enhancing the performance of cement pastes. This paper reviews the work done so far on the application of nanosilica to enhance oilwell cement properties for improved well integrity and successful zonal isolation. Moreover, the paper highlights challenges associated by the use of nanosilica in cement composites. For the purpose of obtaining better performance, the future nanotechnology researches are also suggested.

2. Nanoparticles in cement based materials

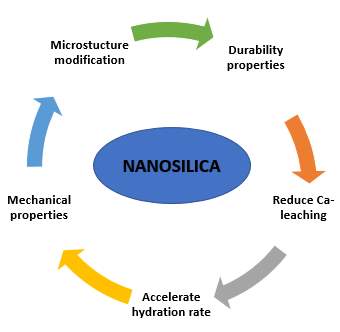

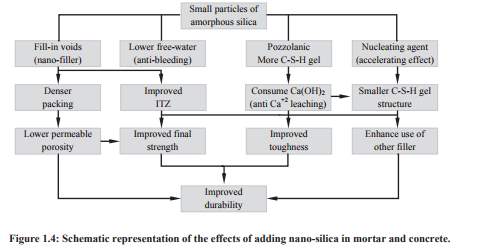

The application of nanotechnology in oilwell cementing job is on the rise as evidenced by several researches carried out in recent years. Though application of nanomaterials in other fields has shown its presence several years ago, the usage of these nano-scale materials in oil and gas well cementing is still to be fully explored [24,25]. The inclusion of nanoparticles into cement improves characteristics of both fresh and hardened cement such as strength, promote hydration reaction, resistance to water penetration, reducing calcium leaching, providing self-cleaning properties e.t.c.[13] (Fig. 3). This enhancement in cement performance has been achieved to a great extent by nanosilica particles due to its pozzolanic activity. Moreover, nanosilica is 100 times smaller than cement grains, it can fill the voids in the young and partially hydrated cement paste, thus developing denser structure with improved microstructure [15].

Apart from nanosilica which seems to be more advantageous nano-scale material in forming hardened cement with high strength, other nanoparticles which have higher potentialities when added into cement include; nano-TiO2, nano-Fe2O3,nano-Al2O3, nano-Cr2O3 and carbon nanotubes (CNTs). There are several studies showing that nano-Fe2O3 and nano-Al2O3 have been widely investigated. Fe2O3 and Al2O3 powders were found to increase compressive strength, flexural and split strength of cement at the same time reducing setting time [15,23,26]. Similarly to nanosilica, some studies revealed that nano-TiO2 enhances early strength and decreasing the setting time of cement paste. Moreover, nano-TiO2 has been found to possess self cleaning properties [10].

However, compared to nano-SiO2, nano-TiO2 has less potential to promote C-S-H gel formation and compressive strength [15]. It has also been reported that nano-TiO2 particles enhance the resistance to water permeability of cementitious materials [27,28]. In comparison with SiO2, Fe2O3 and Al2O3 nanoparticles, application of nano-Cr2O3 in cement slurry is referred to fewer studies. Nevertheless, studies to investigate the mechanical behavior and water permeability of cement containing nano-Cr2O3 have been reported. Apart from strength improvement, water absorption was found to decrease due to a reduction of the amount of pores when nano-Cr2O3 was added in cement as a result of its filler effect [15, 29].

On the other hand, nano-Cr2O3 is not considered the best option compared to other nanoparticles due to toxicity concern of chromium. Recently, it is also reported that CNTs have great potential due to their higher mechanical properties compared to other nanoparticles. CNTs have been researched several times and reported to have a Young Modulus around 1.0 TPa which is five times higher than that of steel , and a tensile strength around 50-100 GPa [15,30,31]. Furthermore, studies have shown that addition of ultra-low concentration of CNTs and carbon nanofibres is able to enhance the electromechanical properties of cement paste enabling such cement composites to be used as self sensing material[13,32,33].

Figure 3. Influence of nanosilica in cementitious system.

3. Effects of nanosilica on oilwell cement properties

A number of studies show that nanosilica is the most widely used nanoparticles in oil well cement to enhance the cement properties due to its pozzolanic and pore filling effects. Due to the increase of reported cases of fluid leakage in oil and gas wells in the world which is associated with poor cement bonding, it is necessary to design cement slurry with added functionalities to ensure well integrity. The nanosilica usage in oilwell cement is a very efficient means to modify properties of cement for successful annular sealing. Moreover, the quantity of nanosilica required is always small [16].

3.1 Effect of nanosilica on setting time and early strength

The incorporation of nanosilica into cement slurry accelerates the cement hydration which in turn reduces the setting time and increases the early age strength of cement[12, 34] (Table 1). In addition, Senff et al.[10], found a reduction in initial setting time and final setting time of pastes after incorporating nanosilica in the cement slurry. As the content of silica nanoparticles is increased, the setting time is reduced signifying that nanomaterials have a faster hydration reaction rate than the cement [26,34-37]. The nanosilica materials promote strength gain at early ages due to its high pozzolanic activity. This pozzolanic reactivity is highly accelerated by higher surface area of nanosilica particles, which then increases the rate of the pozzolanic reaction [15, 38]. It was found that just a small amount of nanosilica particles when added into cement pastes can enhance hydration of tricalcium silicate (C3S), thus improving the rate of early strength gain [12].

Table 1. Standard consistency and setting time of cement with nanosilica[12].

|

Nanosilica |

Standard |

Setting time (min) |

|

|

Initial setting |

Final setting |

||

|

0 0.5 1 1.5 2 2.5 3 |

28 28 29 29 30 30 31 |

145 141 138 138 132 129 123 |

324 300 281 262 240 218 209 |

3.2 Effect on the hydration reaction

The accelerating capability of nanosilica on cement hydration process has been examined by different studies in which the peak of hydration rate is usually noticeably increasing [9,39,40]. Several authors have investigated the role of nanosilica during hydration of cement and revealed that nanosilica is the best accelerators for cement hydration reaction due to its pozzolanic reactivity. The hydration reaction of C3S, C2S and C4AF are accelerated in the presence of nanosilica [41,42,43], and it occurs at every stage of hydration [43]. Fig.5 shows the difference in evolution of heat of hydration in nanosilica added cement and plain cement paste using adiabatic calorimetry[8,10]. In addition, nanosilica with particle size of 4-6nm and Class H oilwell cement were used to examine the role of nanoparticles as hydration accelerators [2,44]. From this study it was reported that the rate of hydration depends on the surface area of nanosilica to be used in the cement. Moreover, the influence of silica fume on the hydration heat of concrete was studied[41,45]. It was found that hydration rate mainly depends on two factors; the water to cement and silica ratio and the silica content. As presented in equation 1, adding silica nanoparticles to cement creates H2SiO42-which reacts with the present Ca2+ to form extra calcium silicate hydrate (C-S-H) which is the main component for strength in hardened cement [8,15,26]. The increased quantity of C-S-H in the cement paste was also reported by Tobón eta l.[21]. The extra C–S–H gel spread in the pore water, acting as nucleation sites for the development of more compact C-S-H phase. While additional C-S-H gel are created, nanosilica also promotes the consumption of Ca(OH)2 resulting into denser and compact microstructure cement with less amount of Ca(OH)2 crystals [8,23,26,35,46,47]. The CH crystals in cement that are formed during hydration are reported to be the source of failure since cracks can easily developed through or within these crystals[41]. The presence of high percentage of CH crystals in cement affects the durability of hardened cement. Therefore, the reaction between nanosilica and Ca(OH)2 reduces the content of CH crystals in the cement as illustrated in Figure 5. This improves not only the mechanical strength of cement but also enhances the durability of hardened cement.

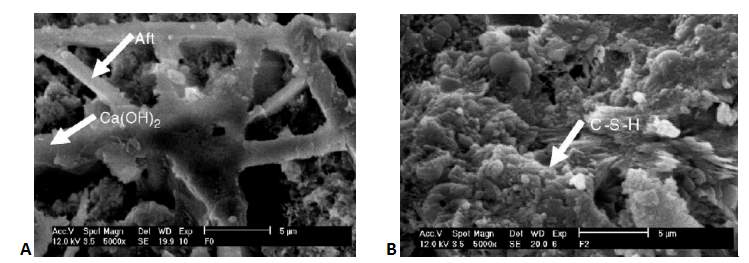

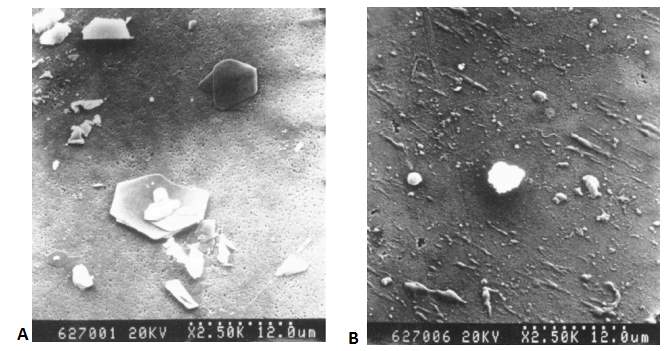

Figure5. SEM image showing CH crystals in (A) plain cement (B) cement with nanosilica. The figure shows that the content of Ca(OH)2 is reduced by nanosilica and it is converted into C-S-H, adapted from Ref.[48].

(from C3S) (from n-SiO2)

Cement + H2O + n-SiO2

Cement + H2O + n-SiO2

Ca2+ + H2SiO42- + H2SiO42- + OH– ……… (1)

(extra)

3.3 Effect on the rheology of cement pastes

Aggarwal et al.[11], Berra et al.[49], Kawashima[50] and Hou et al.[51] examined the rheology of cement slurries having different water to cement ratios and found that the addition of nanosilica greatly increases the water demand of cementitious mixes to retain its workability. This property signifies that addition of high surface area particles to cement pastes cause the need for higher water demand in order to keep the workability of the cement slurry[11]. If the amount of water is kept fixed, as in the original conditions, an increase of nano-SiO2 content will promote the packing of cement particles, decreasing the voids between them and increasing free water, contributing to fluidity in the paste [11,36,52]. However, the decrease of workability obtained by many researchers is explained by the fact that not all the agglomerates act as fillers that occupy the void space between cement particles and release free water. In addition to the high water absorption of nanosilica, these agglomerates will not only act as fillers but also consume free water that originally contributes to fluidity. Therefore, the effect of nanosilica inclusion on the rheological behavior mainly depends on whether the agglomerates can act as fillers or not[15].

3.4Effect on the Mechanical properties of hardened cement

With regard to the influence of nanosilica on the mechanical strength of the hardened cement, incorporation of nanosilica into cement pastes was found to increase the compressive strength to an extent that was dependent on the nanosilica content, water to binder weight ratio (w/b) and curing time[11]. Mechanical properties of hardened cement were studied[7,49,53] along with bond strength[7,11]. It was found that compressive strength was improved with the increase in content of nanosilica at early ages along with increase in pozzolanic activity. Chithra et al.[12], studied the influence of nanosilica on strength of hardened cement. They found that the strength of all nanosilica mixes was higher than the control mix. The strength of cement cubes increased with the percentage of nanosilica addition as shown in Table 2. Moreover, Chithra et al.[12], found that the strength gain is directly attributed to the method of production of nanosilica and the dispersion of nanoparticles in cement based materials. They concluded that the main role of pozzolanic reaction is strength development as well as reducing the pore size distribution.

Table 2. Compressive strength of cement at different curing time[12].

|

Mix ID |

Cement |

Nanosilica (%) |

Compressive strength (MPa) |

||||

|

3 days |

7days |

28days |

56days |

90days |

|||

|

MCN0 MCN0.5 MCN1 MCN1.5 MCN2 MCN2.5 MCN3 |

100 99.5 99 98.5 98 97.5 97 |

0 0.5 1 1.5 2 2.5 3 |

16.3 20.5 24.9 29.4 32.7 31.8 30.4 |

34.9 40.9 42.4 45.5 48.9 46.6 43.8 |

56.5 60.1 63.6 65.7 68.3 66.6 64.7 |

60.6 62.3 64.5 66.9 69.7 67.2 65.2 |

62.7 65.4 66.9 68.4 70.9 68.1 66.4 |

It has been reported that due to its size effect, nanosilica can fill the spaces between C-S-H gel and act as nanofiller to reduce effective porosity/permeability[9]. Aggarwal et al.[11]studied the permeability properties of nanosilica cement and observed that that the addition of nanosilica in cement resulted in reduction in water absorption, rate of water capillary absorption and water permeability than conventional cement. They further reported that water absorption capacity decreased with addition of nanosilica. Reduction in water absorption, rate of water absorption and water permeability has been studied by various researchers[34,54-57]. It was also observed that increasing nanosilica dosage decreased capillary porosity. Fig. 6, shows how the pore structure and its distribution determines the transport behavior of cement paste such as permeability. In addition, it has been reported that cement with nanosilica dosage have high impact on the resistance of chloride ions penetration. A number of researchers have examined the ability of nanosilica cement slurry to resist chloride ions penetration [54,56,57]. These studies revealed that nanosilica cement reduces chloride ions penetration which enhances durability of cement.

Figure6. SEM image showing pore structure in (A) plain cement (B) cement with nanosilica. Nanosilica reduces the number of pores and thus decreasing the water permeability of cement, adopted from [48].

3.6 Microstructure modification

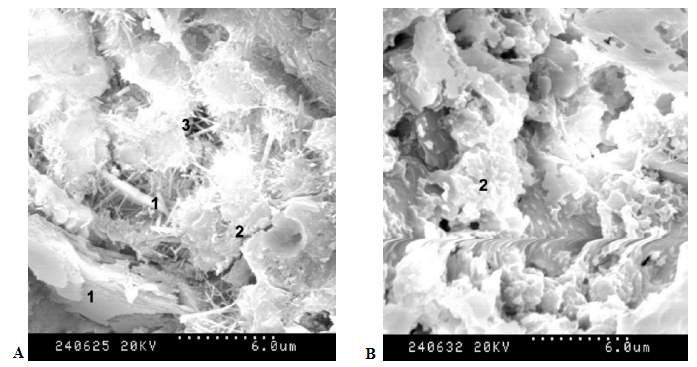

The incorporation of nanosilica positively promotes early hydration of Portland cement and leads to more uniform microstructure with reduced pore size and volume[9,46,56,58]. A well dispersed nanosilica particles in the cement slurry result into a denser microstructure for stronger and durable hardened cement[9,15]. Different material characterization techniques are used to study the microstructure properties of cement sheath. SEM, ESEM and XRD material characterization techniques have been reported to be used in a number of studies[7,8,23,51,53,59-62]. Furthermore, Li et al.[29], based on the SEM images found that nanoparticles are acting as filler and activator to accelerate hydration but also to enhance the microstructure of the cement paste if the nanomaterials are well dispersed. Ji[2005] also through ESEM test found that nanosilica can improve the microstructure and decreases the water permeability of concrete. Based on the mercury intrusion porosimetry study it was found that adding nanosilica into concrete permeability and pore size of concrete was decreased [12, Lin et al]. Bhuvaneshwari et al.[12], from the SEM images observed that nanosilica filled the cement paste pores, more homogeneity for cement paste, by reacting with Ca(OH)2 crystals forming more C-S-H gel[39]. The presence of an extra C-S-H gel fills the pores system causing denser and well packed microstructure of cement [40-44]. Moreover, it was found that the Ca(OH)2 produced during the hydration reaction remains in cement in a crystal form which affects cement properties[28]. But when nanosilica is incorporated into cement, crystallization of Ca(OH)2 is reduced [4, 12, 25, 28] (Figure7).

Figure 7. SEM image showing crystallization in (A) plain cement; (B) nanosilica cement, adopted from [30].

With the emergence of nanotechnology, nanosilica is becoming a promising additive to improve cement properties. The study shows that the inclusion of nanosilica particles into cement has high potential to improve a wide range of fundamental properties. The application of nanosilica into oilwell cement helps to solve problems related to long term zonal isolation to enable the well to reach its full production potential. Nanosilica based cement can strengthen the bond between cement and formations, hence preventing fluid migration into the wellbore, solving problems associated by contamination of the fresh water aquifers and reducing costs related to production and remedial works.

Most of the authors concluded that addition of nanosilica promotes the cement hydration which in turn decreases the setting time and increases the rate of compressive strength. The greatest impact in strength development is experienced at early curing ages due to high Pozzolanic activity of nanosilica at initial stages. Early strength in oilwell cementing is important because it prevents influx of formation fluids during cement setting, and hence improving well integrity.

Based on the review made, the future studies should address the following issues;

- Most of the studies done so far are focused on the influence of nanoparticles such as SiO2, Fe2O3, TiO2, Al2O3, CaCO3, nanoclay and carbon nanotubes to enhance cement properties separately. Researches on the influence of these nanoparticles to modify properties of cement in a combination of two or more kinds of nanoparticles need to be investigated more.

- There is no particular formula or number describing the amount of nanosilica that can be added to cement to make nanomaterials beneficial for the properties of cementitious composites. The optimum nanosilica content to be added into cement needs to be determined depending on the type and average size of nanomaterials.

- Effective dispersion of nanosilica is a challenge requiring thorough study, since nanosilica are not easy to disperse uniformly into cement paste due to their high specific surface areas.

- Many works have been done on mechanical properties and microstructural modification. Other durability properties regarding geochemical downhole conditions such as acid resistance, sulfate resistance and corrosion resistance need to be investigated further.

- Studies show that wide range of properties that make nanoparticles so useful, such as size, shape and surface characteristics, can also cause potential problems if the material is not properly used. Hence, further research results are needed to clarify some environmental and health effects related to nanosilica.

References

[1]Brandl A, Cutler J, Seholm A, et al. Cementing Solutions for Corrosive Well Environments, SPE Drill &

Compl, 2011, 2: 208-219.

[2]Fakoya M F, Shah S N. Emergence of nanotechnology in the oil and gas industry; Emphasis on the application

of silica nanoparticles. Petroleum, 2017, 1-15.

[3]Agbasimalo N, Radonjic M. Experimental study of Portland cement/rock interface in relation to wellbore

stability for carbon capture and storage (CCS).46th US Rock Mech Symp. American Rock Mech Asso, 2012.

[4]Nelson E B, Guillot D. Well Cementing. Developments in Petroleum Science Book Series, Schlumberger, 2nd

edition, 2006.

[5]Nabhani N, Emami M, Moghadam T A B. Application of Nanotechnology and Nanomaterials in Oil and Gas

Industry. The 4th Nanoscience and Nanotechnology Symposium. AIP Conf. Proc, 2011, 1451, 128-131.

[6]Amanullah Md, Al-Tahini A M. Nanotechnology-its significance in smart fluid development for oil and gas field

application, SPE Saudi Arabia Section Technical Symposium, 2009.

[7]Qing Y, Zenan Z, Deyu K, et al. Influence of nano-SiO2 addition on properties of hardened cement paste as

compared with silica fume. Constr &Build Mater, 2007, 21: 539–545.

[8]Senff L, Labrincha J A, Ferreira V M, et al. Effect of nano-silica on rheology and fresh properties of cement

pastes and mortars. Constr Build Mater, 2009, 23, 2487–2491.

[9]Santra A.K, BoulP, Pang X. Influence of Nanomaterials in Oilwell Cement Hydration and Mechanical Properties.

SPE International Oilfield Nanotechnology Conf & Exh, Noordwijk, The Netherlands, 12–14 June 2012, pp 13.

[10]Singh L P, Karade S R, Bhattacharyya S K, et al. Beneficial role of nanosilica in cement based materials – A

review. Constr Build Mater, 2013, (47) 1069–1077.

[11]Aggarwal P, Singh R P, Aggarwal Y. Use of nano-silica in cement based materials. Civil & Env Eng Review

Article, Cogent Eng, 2015, 2:1078018.

[12]Chithra S, Senthil Kumar S R R, Chinnaraju K. The effect of Colloidal Nano-silica on workability, mechanical

and durability properties of High Performance Concrete with Copper slag as partial fine aggregate. Constr &

Build Mat, 2016, 113: 794–804.

[13]Khalil M, Jan B M, Tong C W, Berawi M A. Advanced nanomaterials in oil and gas industry: Design,

application and challenges. Applied Energy, 2017, 191:287-310.

[14]Reddy N A, Meena T. A comprehensive overview on performance of nanosilica concrete. Int J of Phar &

Tech, 2017, 27(1): 5518-5529.

[15]João Pedro Teixeira Silvestre. Nanotechnology in Construction: Towards Structural Applications. Civil

Engineering Master Thesis, University of Lisbon, Portugal, 2015.

[16]El-Diasty A I, Ragab A M S. Applications of Nanotechnology in the Oil & Gas Industry: Latest Trends

Worldwide & Future Challenges in Egypt. North Africa Tech Conf & Exh, Cairo, Egypt, 2013.

[17]Li, G. Properties of high volume fly ash concrete incorporating nano-SiO2. Cem & Conc Research, 2004, 34:

1043-1049.

[18]Byung W J, Chang H K,Ghi H T, et al. Characteristics of cement mortar with nanoSiO2 particles, Constr. Build.

Mater, 2007,21: 1351-1355.

[19]Lin K L, Chang W C, Lin D F, Luo H L, Tsai M C. Effects of nanosilica and different ash particle sizes on the

sludge ash-cement mortar. Journal of Env. Manag. 2008, 88:708-714.

[20]Singh L P, Agarwal S K, Bhattacharyya S K, et al. Preparation of silica nanoparticles and its beneficial role in

cementitious materials. Nanomaterial Nanotechnology, 2011, 1: 44–51.

[21]Tobón J I, Payá J J, Borrachero M V, et al. Mineralogical evolution of Portland cement blended with silica

nanoparticles and its effect on mechanical strength. Constr & Build Mat, 2012, 36: 736–742.

[22]Quercia B G. Application of nanosilica (nS) in concrete mixtures. 8th Fib PhD Symp. Kgs Lyngby Den, 2014.

[23]Bhuvaneshwari B, Sasmal S, Baskaran T, et al. Role of Nano Oxides for Improving Cementitious Building

Materials. Journal of Civil Eng &Sc. JCES, 2012, 1(2): 52-58.

[24]Singh S, Ahmed R. Vital role of nanopolymers in drilling and Stimulations fluid Applications. Paper SPE

130413 presented at the SPE Annual Technical Conference and Exhibtion, Florence, Italy, 2010.

[25]Patil R C, Deshpande A. Use of nanomaterials in cementing applications, SPE International Oilfield

Nanotechnology Conference and Exhibition, 2012.

[26]Khayati G R, Ghasabe H M, Karfarma M. A survey on the application of oxide nanoparticles for improving

concrete processing. Advances in Concrete Construction, 2015, 3(2): 145-159.

[27]Nazari A, Riahi S. The effects of TiO2 nanoparticles on properties of binary blended concrete. Journal of

Composite Materials, 2011, 45:1181-1188.

[28]Cárdenas C, Tobón J I, García C, Vila J. Functionalized building materials: Photocatalytic abatement of NOx

by cement pastes blended with TiO2 nanoparticles”, Constr and Build Mater., 2012, 36:820–825.

[29]Nazari A, Riahi S. Optimization mechanical properties of Cr2O3 nanoparticle binary blended cementitious

composite. Journal of Composite Materials, 2010, 45:943-948.

[30]Sinnott, S B, Andrews R. Carbon Nanotubes; Synthesis, properties and application. Critical Reviews in Solid

State and Materials Science, 2001, 26:145-249.

[31]Silvestre N, Faria B, Lopes J N. A Molecular dynamics study on the thickness and post critical strength of

carbon nanotubes, Composite Structures, 2012, 94:1352-1358.

[32]Wong I, Loh K J, Wu R, Garg N.Effects of ultra low carbon nanotubes on electromechanical properties of

cement paste: Nanotechnology in construction. New York, Springer Int Pub, 2015, 371-376.

[33]D’Alessandro A, Rallin M, Ubertini F, Materazzi A L, Kenny J M. Investigations on scalable fabrication

procedures for self-sensing carbon nanotube cement matrix composites for SHM applications. Cem Concr

Compos 2016, 65:200- 213.

[34]Zhang M H, Islam J, Peethamparan S. Use of nano-silica to increase early strength and reduce setting time of

Concrete with high volumes of slag. Cement and Concrete Composites, 2012, 34: 650–662.

[35]Sadrmomtazi A, Barzegar A. Assessment of the effect of Nano-SiO2 on physical and mechanical properties of

self compacting concrete containing rice husk ash. Second International Conference on Sustainable

Construction Materials and Technologies, University of Politecnica dell, Marche, Ancona, Italy, 2010.

[36]Ltifi M, Guefrech A, Mounanga P, et al. Experimental study of the effect of addition of nano-silica on the

behaviour of cement mortars Mounir. ProcediaEng, 2011, 10: 900–905.

[37]Chen J, Kou S, Poon C. Hydration and properties of nano-TiO2 blended cement composites, Cem & Conc

Compo, 2012, 34:642–649.

[38]Chong J Z, Sutan N M, Yakub I. Characterization of early pozzolanic reaction of calcium hydroxide and

calcium silicate hydrate for nanosilica modified cement paste, UNIMAS E-J. Civil Eng., 2012, 4:6–10.

[39]Thomas J J, Jennings H M, Chen J J. Influence of Nucleation Seeding on the Hydration Mechanisms of

Tricalcium Silicate and Cement. Journal of Physical Chemistry, 2009, 113: 4327–4334.

[40]Land G, Stephan D. The Influence of Nano-Silica on the Hydration of Ordinary Portland Cement. Journal of

Material Science, 2012, 47: 1011–1017.

[41]Siddique R, Khan M I. Supplimentary Cementing Materials. Engineering Materials, Springer, 2011.

[42]Kurdowski W, Nocun-Wczelik W. The tricalcium silicate hydration in the presence of active silica. Cem. Concr.

Res, 1983, 13(3), 341-348.

[43]Uchikawa H, Uchida S. Influence of pozzolans on the hydration of C3S. In, Seventh International Congress on

the Chemistry of cement, Paris, 1980, 4:23-29.

[44]Pang X, Boul P J, Jimenez W C. Nanosilica as accelerators in oilwell cementing at low temperatures, SPE

Drill, Complet, 2009,29(01):98-105.

[45]Kadri E H, Duval R. Hydration heat kinetics of concrete with silica fume. Contruct.Build Mater, 2009,

23(11):3388-3392.

[46]Gaitero J J, Campillo I, Guerrero A. Reduction of the Calcium Leaching Rate of Cement Paste by Addition of

Silica Nanoparticles. Cement and Concrete Research, 2008,38: 1112–1118.

[47]Gaitero J J, Campillo I, Mondal P, et al. Small Changes Can Make a Great Difference. Transportation Research

Record No. 2141, 2010, 1–5.

[48]Vegesna M M. The Advancements of Cementitious Materials Through Nanotechnology. Master Thesis, Texas

Tech University, Texas, 2013. http://hdl.handle.net/2346/58446.

[49]Berra M, Carassiti F, Mangialardi T, Paolini A E, Sebastiani M. Effects of nanosilica addition on workability

and compressive strength of Portland cement pastes. Construction and Building Materials, 2012, 35: 666–675.

[50]Kawashima S, Hou P, Corr D J, Shah S P. Modification of cement-based materials with nanoparticles. Cement

and Concrete Composites, 2012, 36: 8–15.

[51]Hou P, Kawashima S, Kong D, et al. Modification effects of colloidal nano SiO2 on cement hydration and its gel

property. Composites Part B:Engineering, 2013, 45: 440–448.

[52]Kong D, Su Y, Du X, Yang Y, et al. Influence of nano-silica agglomeration on fresh properties of cement

pastes, Construction and Building Materials, 2013, 43:557–562.

[53]Stefanidou M. Influence of nano-SiO2 on the Portland cement pastes. Composites Part B: Engineering, 2012, 43:

2706– 2710.

[54]Zhang M H, Li H. Pore structure and chloride permeability of concrete containing nano-particles for pavement.

Construction and Building Materials, 2011, 25: 608– 616.

[55]Li, H, Zhang M H, Ou, J P. Flexual fatigue performance of concreatecontaining nanoparticles for pavement. Int.

J. Fatigue, 2007, 29:1292-1301.

[56]Jalal M, Pouladkhan R A, Norouzi H, et al. Chloride penetration, water absorption and electrical resistivity of

high performance concrete containing nano silica and silica fume. J of American Science, 2012, 8: 278–284.

[57]Zhang M, Islam J. Use of nano-silica to reduce setting time and increase early strength of concretes with high

volumes of fly ash or slag. Constr. Build. Mater. 2012, 29:573–580.

[58]Ozyildirim C, Zegetosky C. Exploratory Investigation of Nanomaterials to Improve Strength and Permeability

of Concrete. Transportation Research Record No. 2142, 2010, 1–8.

[59]Li H, Xiao H G, Ou J P. A study on mechanical and pressure-sensitive properties of cement mortar with

nanophase materials. Cement and Concrete Research, 2004, 34:435–438.

[60]Kong D, Du X, Wei S, et al. Influence of nano-silica agglomeration on microstructure and properties of the

hardened cement-based materials. Construction and Building Materials, 2012, 37:707–715.

[61]Pourjavadi A, Fakoorpoor S M, Khaloo A, et al. Improving the performance of cement-based composites

containing superabsorbent polymers by utilization of nano-SiO2 particles. Mater. and Desig., 2012, 42:94–101.

[62]El-Bakya S A, Yehiab S, Khalila I S. Influence of nanosilica addition on properties of fresh and hardened

cement mortar. Brno, Czech Republic, EU, 2013, 10: 16-18.

[16]Chong J Z, Sutan N M, Yakub I. Characterization of early pozzolanic reaction of calcium hydroxide and

calcium silicate hydrate for nanosilica modified cement paste, UNIMAS E-J. Civil Eng., 2012, 4:6–10.

[40]Bjornstrom J, Martinelli A, Matic A, et al. Accelerating effects of colloidal nano-silica for beneficial calcium

silicate hydrate formation in cement, Chem. Phys. Lett. 2004, 392(1): 242–248.

[42]Ji T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2, Cem.

Concr. Res. 2005,35: 1943–1947.

[45]Allen A J, Livingstone R A. Relationship between differences in silica fumes additives and fine scale

microsturcture evolution in cement based materials. Advanced Cem-Based Mater, 1998, 8:118-131.

[46]Ali A H, Kandeel A M, Ouda A S. Hydration characteristics of limestone filled cement pastes. Chem & Mater

Research, 2013, 5:68-73.

[47]Bahadori H, Hosseini P. Reduction of cement consumption by the aid of silica nanoparticles. Journal of Civil

Eng and Manag, 2012, 18:416-425.

[48]Behfarnia K, Salemi N. The effects of nano-silica and nano-alumina on frost resistance of normal concrete.

Constr & Build Mater, 2013, 48:580-584.

[49]Li H, Xiao H, Yuan J, Ou J. Microstructure of cement mortar with nanoparticles. Composites Part B, Eng,

2004, 35:185-189.

[50]Nazari A, Riahi S. Improvement compressive strength of concrete in different curing media by alumina

nanoparticles. Mater Sci & Eng, 2011, 528:1183-1191.

[51]Qing Y, Zenan Z, Li S, Rongshen C. A comparative study on the pozzolanic activity between nano-silica and

silica fumes. Journal of Wuhan University of Technology, Mater Sc, Ed, 2006, 21:153-157.

[52]Sachez F, Sobolev K. Nanotechnology in concrete-A Review. Constr & Build Mater, 2010, 24:2060-20171.

[53]Seff L, Hotza D, Repette W L et al. Rheolegical characterization of cement pastes with nanosilica, silica fumes

and superplasters additions. Advance in Applied Ceramics, Structural, Functional & Bioceramics, 2010,

109:213-218.

[54]Sidique R. Utilization of silica fumes in concrete. Review of hardened properties. Resources, Conservation and

Recycling, 2011, 55: 923-932.

[55]Sobolev K, Ferrara M. How Nanotechnology can change the concrete world. Part -1. American Bulletin, 2005,

84(10):14-17.

[56]Taylor H W F. Cement Chemistry. Academic Press, New York, 1990.

[57]Zhang M H, Tam C T, Leow M P. Effect of water to cementitious materials ratio and silica fumes on the

autogenous shrinkage of concrete. Cem. Concr, Res., 2003, 33(10):1687-1694.

[58]Silica Fume Association. Silica fume manual, 38860 Sierra Lane, Lovettsville, VA 20180, USA, 2005.

[59]Zhenhai X, Zhonghui Z, Peng D et al. Effects of nanosilica on hydration properties of tricalcium silicate,

Constr, Build Mater, 2016, 125:1169-1177.

[60]Zhang M H, Islam J. Use of nanosilica to reduce setting time and increase early strength of concretes with high

volumes of fly ash or slag. Constr.Build Mater., 2012, 29:573-580.

[61]Kontoleontos F, Tsakiridis P E, Marinos A et al. Influence of colloidal nanosilica on ultrafine cement hydration.

Physiochemical and micro-structural characterization, Constr Build Mater, 2012, 25:347-360.

[62]Mohamed H, Ali A I, Ismail M N et al. Behaviour of composite cement pastes containing silica nanoparticles at

elevated temperature, Contr. Build Mater., 2014, 70:339-350.

[63]Diab AM, Awad A E M, Elyamany H E et al. Guidelines in compressive strength assessment of concrete

modified with silica fumes due to magnesium sulphate attack. Constr Build Mater, 2012, 36:311-318.

[64]Kim K, Heo Y, Kang S et al. Effect of sodium silicate and ethyl silicate based nanosilica on pore structure of

cement composites, Cem& Con. Res.,2014, 49:84-91.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Chemistry"

Chemistry is a science involving the study of the elements and matter at the atomic and molecular level including their composition, structure, properties, behaviour, and how they react or combine.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: